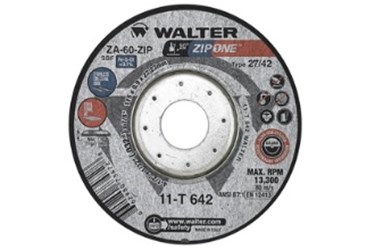

New ZIP ONE TYPE 27 Ultra-Thin Cutting Wheel From Walter Surface Technologies

Walter Surface Technologies has launched the new ZIP ONE TYPE 27, the latest addition to the ZIP ONE line of the company's high performance extra thin cut-off wheels, designed for optimal cutting in thin gage metal (under 1/8-inch, 3mm thick). With the same ultra-thin design as the current 1mm ZIP ONE TYPE 1 (FLAT) cutting wheel, the ZIP ONE TYPE 27 features a special raised centre for extra rigidity, durability and thinness. The unique design of the TYPE 27 centre hub allows for a larger cutting surface than standard progressive hubs, while enabling straighter, sharper, more precise and higher speed cuts for flush cutting applications.

“Our industry-leading ZIP ONE received tremendous market acceptance from its launch this past January. The ZIP ONE TYPE 27 is expected to hit the market with as much excitement. The product has been three years in the making and our engineers have delivered an ultra-thin cutting wheel that not only offers the most durable and rigid TYPE 27 in the industry, but one that provides sharper, straighter and more precise cuts when compared to competing TYPE 27 products. That’s a key technical distinction that results in better productivity for the customer”, states Patrick Lapointe, Vice President Research and Development, Walter Surface Technologies.

Featuring the same ultra-thin cutting wheel features as the ZIP ONE TYPE 1, the new ZIP ONE TYPE 27 is a specially reinforced, bonded wheel with a proprietary mix of high performance abrasives that Walter Surface Technologies says delivers the thinnest, straightest cuts while resisting bending.

Manufactured with an iron-free mix, the company says ZIP ONE TYPE 27 cuts cooler and faster and is guaranteed not to contaminate stainless steel. It avoids discoloration of the work piece and cuts burr-free, reducing post-cut finishing. Walter Surface Technologies also says the ZIP ONE TYPE 27 wheel has a significantly longer life compared to other ultra-thin wheels, offering more cuts per wheel and the lowest price per cut. For more information, visit walter.com.

Source: Walter Surface Technologies