CCAT Named Center Of Excellence For Additive Manufacturing Services

CCAT Advanced Manufacturing Center is recognized for excellence in the manufacture, repair, rework and coating of metal components using Optomec LENS 3D Printers.

East Hartford, CT (PRWEB) - Connecticut Center for Advanced Technology, Inc. (CCAT), today announced that its Advanced Manufacturing Center (AMC) has been named a Center of Excellence for additive manufacturing services by Optomec Inc., a leading manufacturer of laser based 3D printers for metals.

As an official Center of Excellence, CCAT’s Advanced Manufacturing Center offers unique expertise, research and development work in the use of Optomec’s proprietary LENS 3D Printers used for the manufacture, repair, rework and coating of metal components.

“We are honored to be named as a Center of Excellence by Optomec, a recognized leader in the field of additive manufacturing systems,” said Elliot Ginsberg, president and CEO, CCAT. “We look forward to partnering with Optomec to provide state-of-the-art laser additive manufacturing support to manufacturers and government agencies regionally and nationally.”

CCAT's AMC readily serves as a national resource for laser processing, additive manufacturing, precision machining and digital manufacturing and provides services that include 5-axis machining, non-contact inspection and machining optimization. To ensure that CCAT is the go-to resource and best practices partner for manufacturers, equipment in the AMC is frequently updated to offer customers the latest in advanced manufacturing technology.

“We are proud to name CCAT as a Center of Excellence for LENS services,” said Richard Grylls, Ph.D. LENS general manager, Optomec. “As a company known for innovation in the development of advanced manufacturing systems, we recognize CCAT’s research and manufacturing technology expertise. We are confident in their ability to use LENS 3D Printing systems to provide outstanding service to the full range of customers they serve, from small Connecticut manufacturers to federal agencies nationwide.”

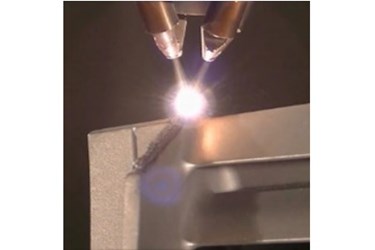

According to Dr. Grylls, the LENS 850 R system at the AMC uses a high-power laser to fuse powdered metals into fully dense 3-dimensional structures. The LENS 3D Printer uses the data contained in a Computer-Aided Design (CAD) solid model to automatically drive the LENS process as it builds up a component layer by layer. For more information on Optomec LENS 3D Printers for metals go to http://www.optomec.com/Additive-Manufacturing-Systems.

“With the highly advanced manufacturing technology of Optomec’s LENS 3D Printing system we are able to make a difference for our customers,” stated Ginsberg. “It enhances the capabilities and services we offer at the AMC to help companies generate topline growth, enhance bottom-line savings, and succeed in today’s competitive global market.”

About CCAT

Connecticut Center for Advanced Technology, Inc. (CCAT) is a non-profit, economic development organization that leads and partners with industry, academia and government statewide and across the nation to help organizations succeed in today’s global market. Through its specialized centers of excellence in manufacturing technology, education and workforce development, alternative energy and information technology, CCAT provides expertise to research and develop unique solutions that increase efficiencies and boost competitiveness. CCAT is headquartered in East Hartford, Connecticut.

About Optomec

Optomec is a privately held, rapidly growing supplier of Additive Manufacturing systems. Optomec’s patented Aerosol Jet Systems for printed electronics and LENS 3D Printers for metal components are used by industry to reduce product cost and improve performance. Together, these unique printing solutions work with the broadest spectrum of functional materials, ranging from electronic inks to structural metals and even biological matter. Optomec has more than 150 marquee customers around the world, targeting production applications in the electronics, energy, life sciences and aerospace industries.

Source: PRWeb

View original release here: http://www.prweb.com/releases/2013/10/prweb11187271.htm